Fusion 360 Design Types

Timeline or Parametric Designs

Fusion 360 offers designers multiple ways to model. Think of this like there are multiple ways to carve a statue. You can chisel and hammer it out of stone, you can sculpt it from clay or you can chainsaw carve it from wood. Each method and material can create a likeness but there are designs better suited to one method more than another. Each method will leave traces on how the form was created. Similarly Fusion 360’s different methods have advantages, disadvantages and best practices. It can be incredibly powerful to have these options once you understand their strengths and weakness. In the beginning it can be confusing and overwhelming. Hopefully this outline gives you some tips to learning when to use these different methods.

We can divide up the multiple modeling methods into two top categories.

- Timeline Designs ( also know as parametric )

- Direct Designs

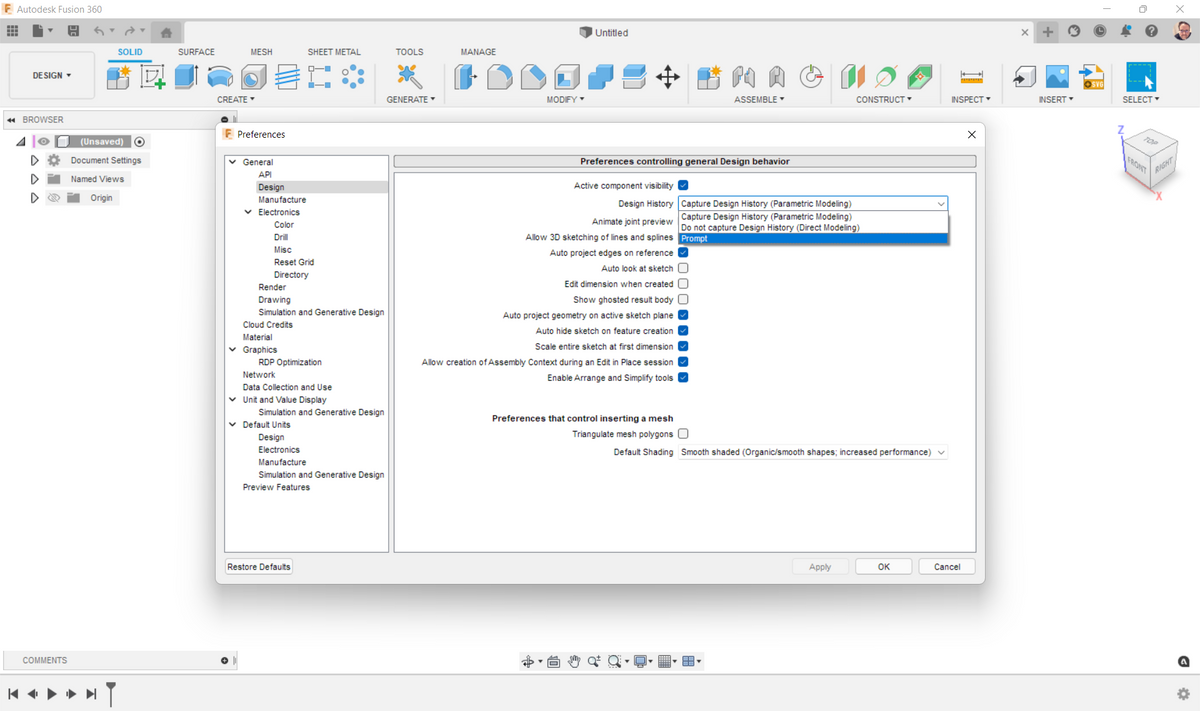

These types are defined and stored by the Document that you store in your projects. By default, new design you create yourself are Timeline designs. Imported designs in Fusion 360 are Direct Designs. These defaults are chosen to provide the easiest on-boarding for users who may not understand when to use which. As you learn more you will see each design type’s advantages and learn when to start with one over another and why you might want to switch from one to the other.

Finally, each type, timeline or direct, offers multiple modeling methods:

- Wireframe/Sketch

- NURBs Solids/Surfaces

- Assembly

- Triangle Mesh, Polygonal Mesh and Quad Mesh

- TSpline ( type of sub-division surface)

We won’t go into too much detail here on when to use these different modeling methods because the effect of choosing a type, direct or timeline will be best understand as we look at modeling in more general terms. To learn more about when to use each modeling type you can read more about their advantages and disadvantages in a future blog post.

Both timeline and direct designs create 3D geometry. This 3D geometry is what you create drawings, toolpaths or 3D print from. How we get to the geometry is where the differences lie.

Timeline Designs

Timeline or Parametric design describes a specific style of 3D design that uses sketches, dimensions, constraints, and equations to describe designs. These concepts will be explained more a little latter. There are many other types of 3D design, but parametric design has grown to a very common way to describe the design of 3D mechanical products. Parametrics offer many benefits in able to change designs and try new ideas.

In order to use parametric to its full potential some skills needs to be developed. These skills will allow you to use parametrics to capture the form, fit, and function of your ideas in 3D.

Parametric designs, here on out called Timeline designs, are a lot like a recipe. If you follow the recipe you can build the same design over and over. The timeline is an ordered list of very specific simple operations. Each step builds on the last. Each operation creates a piece of the geometry.

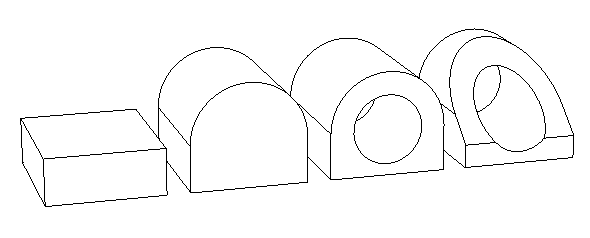

For example here are 4 simple steps that combine to make a more complicated shape.

Each operations geometry combines with with the geometry from earlier operations and produces a final geometry result. Just remember a timeline design’s geometry is a result of the history of steps.

Timeline designs are a good when it comes to design that involve complex and highly detailed parts. They are also good when you produce a range or family of products that only have minor variations. With parametric modelling, the designer has the ability to:

- Regenerate or rebuild a design as design changes are needed

- Capture design intent, making it fast and easy to define how the model should behave when a change is made

- Define and automate the creation of families of parts

However timeline designs are not without some disadvantages. The main limitations that are:

- Constrain creativity in concept design work, especially when wanting to explore many design variations or complex organic shapes

- Unexpected design changes take longer make

- Working with designs from other CAD tools

Direct Designs

With direct modeling you are capturing the raw geometry directly. There is no recipe or rebuilding. You work directly on the topology of faces and edges and you can cut, split rework very quickly on the geometry directly. Hence the name Direct. This is ideal for concepting and ideation work, where you want to be able to explore a wide range of design variations or ideas without being limited.

- Make 3D models very quickly, perfect for ideation

- Make edits with ease without worrying about effects of changes to other parts of a design

- Working with imported data

Direct does have limitations:

- Harder to build in design intent (equations) or families of parts

- Harder to deal with design changes where you are deleting, splitting or consuming faces. This might be a little hard to understand right as you get started so we will explain a little further.

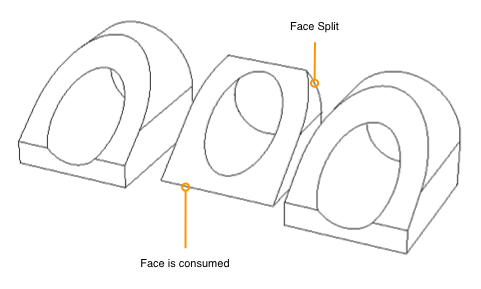

Take the example below. Starting with the design on the left, we change the design by making the angled face cut into the model more. In doing so the end face is removed and the outer face is split.

If we wanted to change this design back to the original shape we would have problems simply moving the angle face because the end face is gone, it was consumed and the outer face would have to merge two faces back into one. Suffice it to say, direct modeling can be very fast and free but there are a few cases such as these that can be counterintuitive and limiting.

Final Thoughts

The advantages of timeline or direct mean that the ideal solution for product design is a hybrid approach. It means being able to enjoy the choice of either, without having to worry about being limited by their limitations.

We suggest leaving the default settings for new designs and imported designs. Knowing why they are different is the first step in learning how to take advantage of the tools. Also, knowing that you have the both timeline and direct modeling tools always available is an extra advantage you have over other common 3D design tools that are limited to only one type

Comments ()